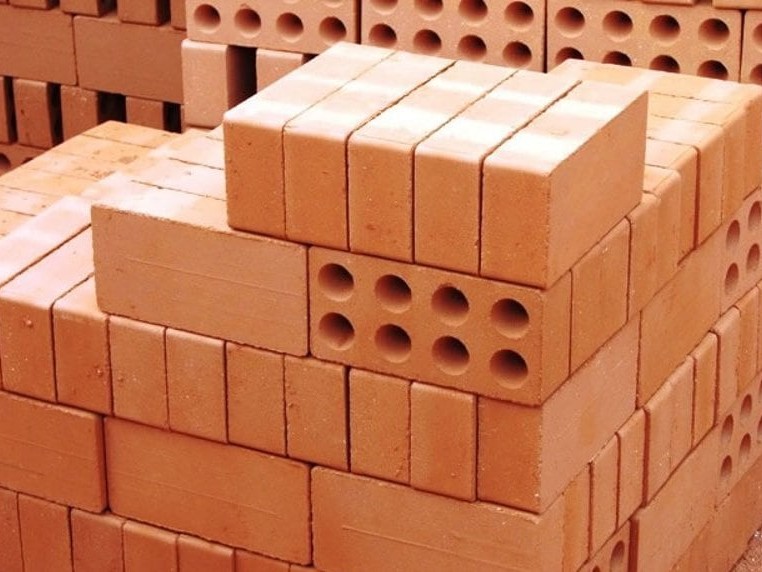

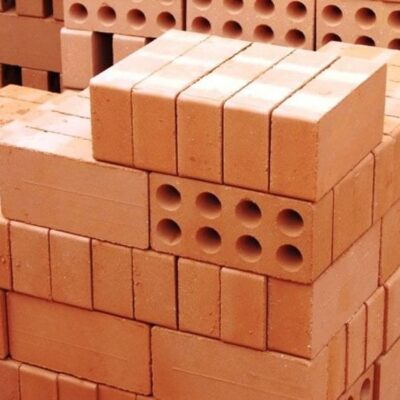

Terracotta bricks (Red bricks, tunnel bricks)

Terracotta bricks, also known as red bricks or tunnel bricks, represent one of the most enduring and versatile building materials in the world. Combining natural aesthetics with exceptional durability, they are a preferred choice for residential, commercial, and architectural projects.

Crafted from high-quality clay and fired at high temperatures, terracotta bricks deliver strength, weather resistance, and a warm, natural color that enhances any construction. Whether for exterior walls, landscaping, or decorative architecture, they bring timeless appeal and structural reliability to every project.

1. Premium Raw Materials

Each brick is made from refined natural clay, ensuring superior quality and consistency:

-

High-grade clay: Sourced from rich deposits, offering excellent plasticity and binding properties.

-

Natural minerals: Provide the distinctive red hue and density of traditional terracotta.

-

Controlled moisture content: Ensures uniform drying and firing results.

-

Eco-friendly composition: 100% natural materials, non-toxic, and sustainable.

The combination of pure clay and controlled production guarantees bricks with optimal hardness, color consistency, and long-term durability.

2. Modern Production Process

Our terracotta bricks are manufactured using tunnel kiln technology, a modern method that ensures uniform firing and consistent quality across every batch:

-

Mixing and molding: Clay is refined, homogenized, and shaped into precise molds.

-

Drying process: Bricks are air- or machine-dried to remove excess moisture before firing.

-

Firing in tunnel kiln: Controlled temperatures (900–1,100°C) guarantee perfect hardness and even color.

-

Quality inspection: Each brick is tested for compressive strength, water absorption, and dimensional accuracy.

This process ensures that each brick meets international standards and maintains superior physical and aesthetic properties.

3. Distinctive Features and Advantages

Terracotta bricks are valued for their durability, beauty, and versatility:

-

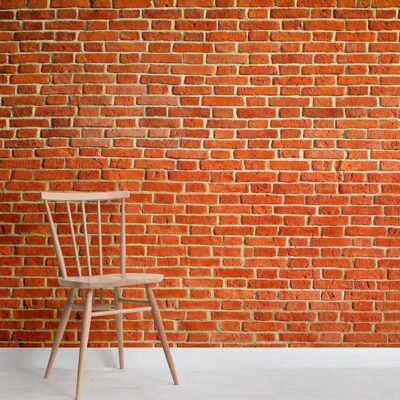

Natural red color: Rich, warm tones that enhance both modern and traditional architecture.

-

High compressive strength: Excellent load-bearing capacity for structural applications.

-

Weather and fire resistance: Suitable for various climates and construction environments.

-

Thermal and acoustic insulation: Keeps interiors cool in summer, warm in winter, and quiet.

-

Low maintenance: Resistant to fading, mold, and deterioration.

-

Eco-friendly production: Made from natural materials with minimal environmental impact.

Their timeless appearance and practical benefits make them ideal for exterior walls, fences, pavements, facades, and decorative structures.

4. Product Range and Applications

Our terracotta bricks come in various sizes and finishes to suit diverse architectural requirements:

-

Red bricks: Classic construction bricks with natural red color, widely used in residential housing and commercial buildings.

-

Tunnel bricks: Fired using continuous tunnel kilns for higher consistency, strength, and precision.

-

Hollow and solid options: For both structural and decorative purposes.

-

Surface options: Smooth, rustic, or sand-textured finishes available upon request.

Applications include:

-

Residential and commercial buildings

-

Garden and landscape walls

-

Architectural facades and heritage restorations

-

Interior decorative designs (exposed brick walls)

5. Technical Specifications

| Feature | Details |

|---|---|

| Product Name | Terracotta Bricks (Red Bricks, Tunnel Bricks) |

| Material | 100% Natural Clay |

| Size Options | Standard: 190 × 90 × 55 mm (Custom sizes available) |

| Color | Natural Red / Burnt Red / Rustic |

| Compressive Strength | 80–150 kg/cm² (depending on type) |

| Water Absorption | ≤ 15% |

| Firing Method | Tunnel Kiln |

| Surface Finish | Smooth / Textured / Rustic |

| Origin | Vietnam |

6. Why Choose Our Terracotta Bricks

-

High durability: Withstand extreme weather and mechanical stress.

-

Excellent insulation: Maintain thermal balance and energy efficiency.

-

Aesthetic appeal: Natural red tones bring warmth and character to architecture.

-

Eco-conscious production: Sustainable materials and energy-efficient kiln technology.

-

International standards: Tested for strength, absorption, and dimensional accuracy.

-

Customizable options: Sizes, finishes, and packaging tailored to client needs.

Our terracotta bricks are ideal for construction companies, architects, and distributors seeking reliable, export-quality building materials with a natural aesthetic.

7. Customization and Export Options

To serve global markets, we offer flexible customization and export support:

-

Size and shape: Custom molds and dimensions available for special designs.

-

Color variations: Adjusted firing temperatures for different red and brown tones.

-

Packaging: Palletized and wrapped for secure international shipping.

-

Private labeling: OEM and ODM services for distributors and retailers.

-

Target markets: Japan, Korea, EU, USA, and Middle Eastern countries.

Our production capacity and consistent quality make us a trusted supplier for both large-scale construction projects and retail distribution.

8. Conclusion

Terracotta Bricks (Red Bricks, Tunnel Bricks) combine tradition, strength, and natural beauty in one versatile material. With advanced tunnel kiln production, eco-friendly clay, and refined craftsmanship, they deliver exceptional performance and enduring charm.

Perfect for export, residential construction, or decorative architecture, these bricks embody the timeless appeal of natural terracotta — strong, sustainable, and beautiful. Each brick tells a story of craftsmanship and heritage, building not only structures but also long-lasting value.