53. Structural Steel Sections – The Ideal Material for Modern Construction Projects

Structural steel sections are essential materials in today’s construction and industrial engineering sectors. With exceptional durability, load-bearing capacity, and design flexibility, they are widely used in core structures such as beams, columns, roofing frames, and heavy-duty support systems.

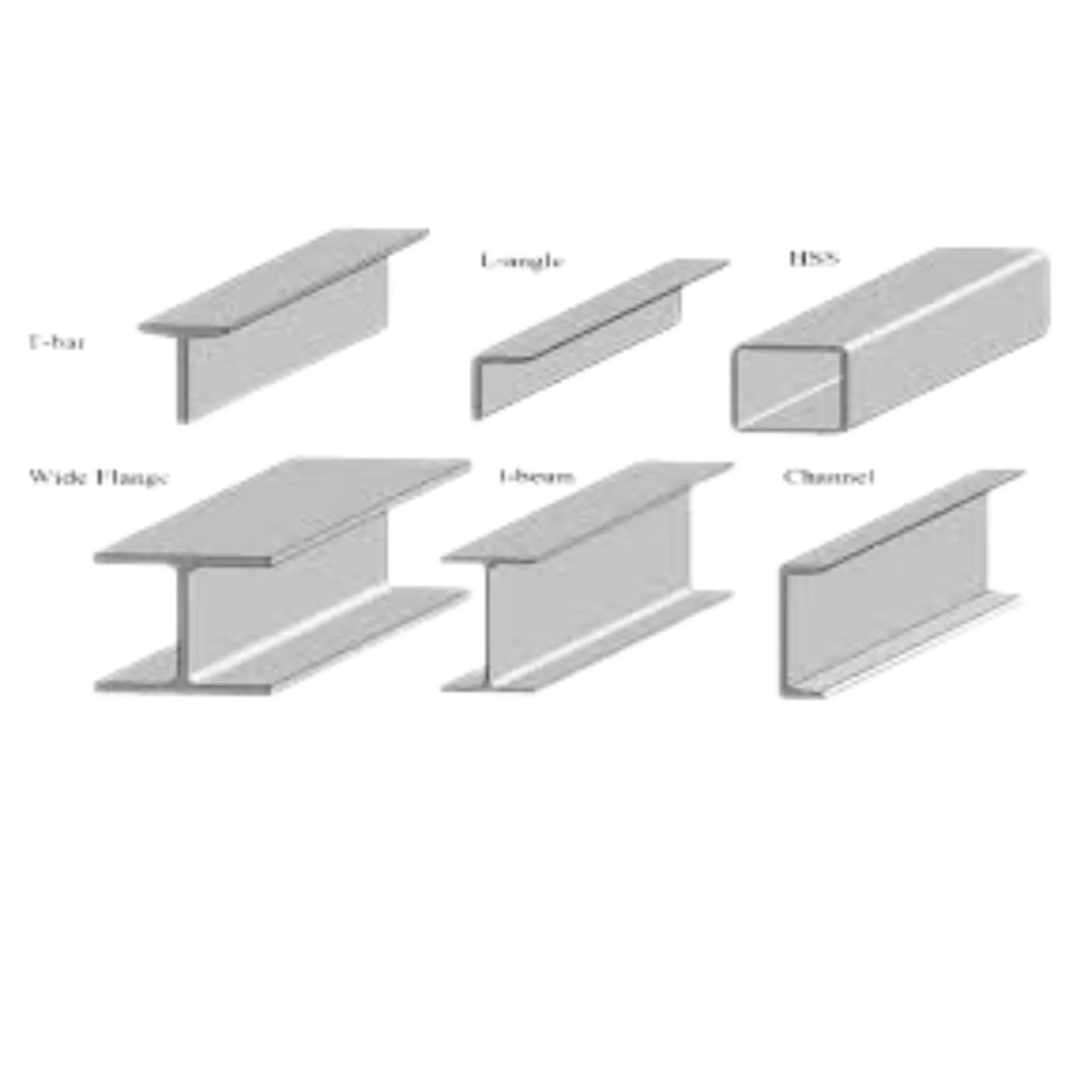

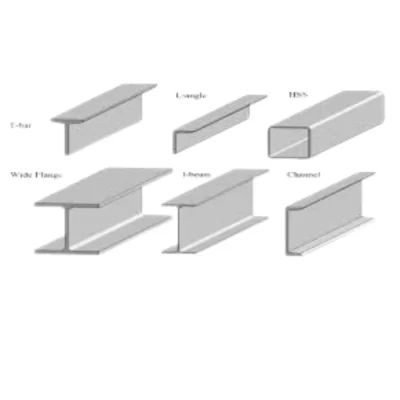

Popular Types of Structural Steel Sections

-

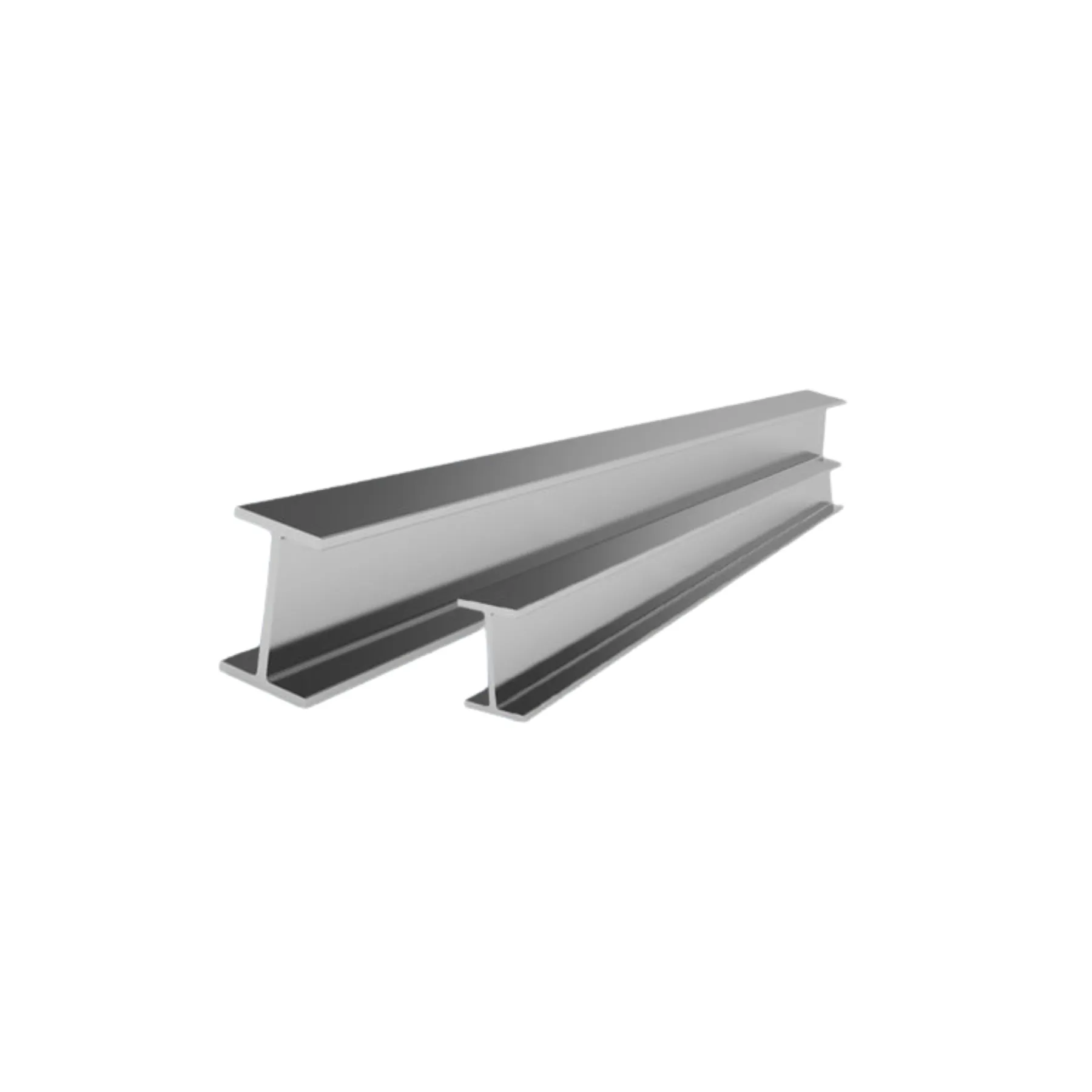

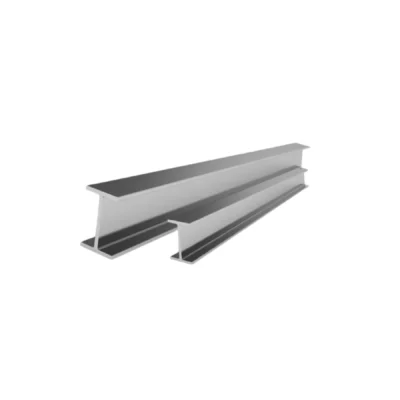

H and I-Beams: Commonly used in heavy-load structures such as steel-framed buildings, bridges, telecom towers, and high-rise constructions.

-

U-Channels: Ideal for purlins, support frames, and secondary structures due to their lightweight and ease of installation.

-

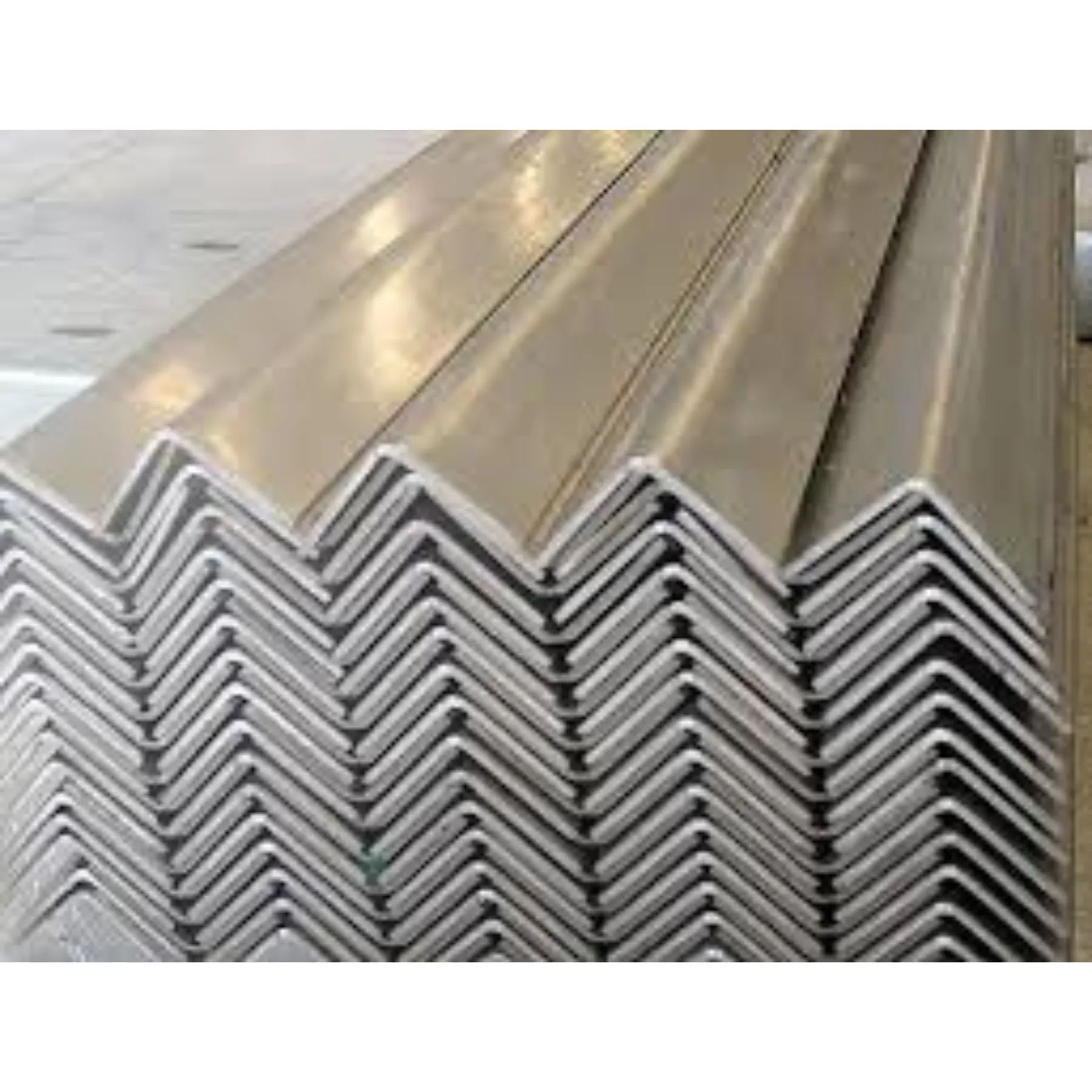

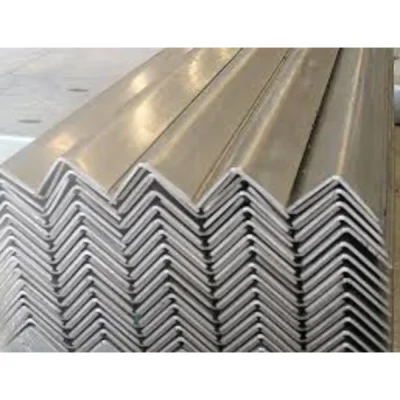

Angle Steel (V or L-shaped): Used for frame reinforcement, door frames, railings, and lightweight steel structures.

-

T and Z Sections: Suitable for roofing frameworks, special structural elements, and twisting-resistant applications.

Outstanding Advantages

-

Excellent load-bearing strength, maintaining shape under heavy pressure.

-

High corrosion and oxidation resistance, especially when galvanized or powder coated.

-

Easy fabrication, cutting, and welding; quick installation helps reduce construction time and costs.

-

Meets international standards such as JIS, ASTM, and TCVN.

Applications Across Industries

-

Industrial buildings, pre-engineered steel structures, warehouses, substations

-

Bridge construction, railways, telecom towers

-

Mechanical fabrication: machine frames, storage tanks, oil rigs

-

Load-bearing furniture and systems: warehouse shelves, railings, heavy-duty flooring

Flexible Specifications & Sizes

Common options include:

-

Lengths: 6 m, 12 m or custom-cut upon request

-

Thickness: 3 mm to 30 mm

-

Steel grades: Q235, SS400, A36, or equivalents

-

Shapes: H200, H250, U100, angle steel types to fit architectural designs