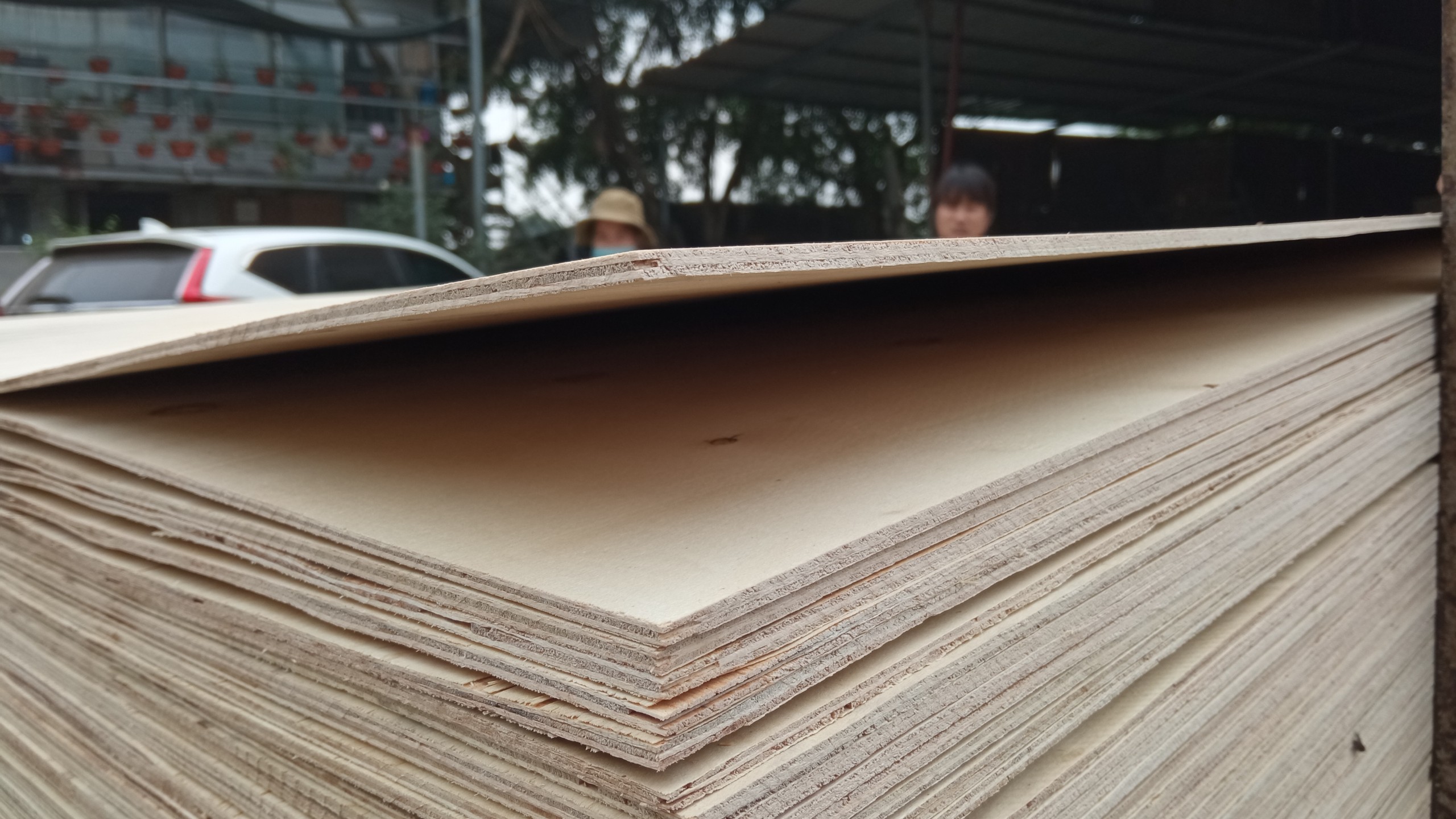

Plywood plywood

Plywood is one of the most versatile and widely used engineered wood products in the world. It is made by bonding thin layers of wood veneers together with the grain of each layer rotated at right angles to adjacent layers. This cross-grain structure gives plywood exceptional strength, stability, and resistance to warping — making it ideal for construction, furniture production, interior decoration, and packaging.

What Is Plywood?

Plywood is a composite wood panel created by gluing together multiple thin veneers (usually 3 to 13 layers) under high pressure and temperature. Each veneer layer is oriented perpendicular to the previous one, creating a strong and dimensionally stable panel.

This structure distributes loads evenly across the surface and minimizes the natural weaknesses of solid wood. Depending on the type of adhesive and wood species used, plywood can be tailored for interior or exterior applications, structural use, or decorative purposes.

Key Features and Advantages

1. High Strength and Stability

Thanks to its cross-laminated construction, plywood is stronger and more stable than regular wood boards. It resists splitting, warping, and shrinking — even under humidity and temperature fluctuations.

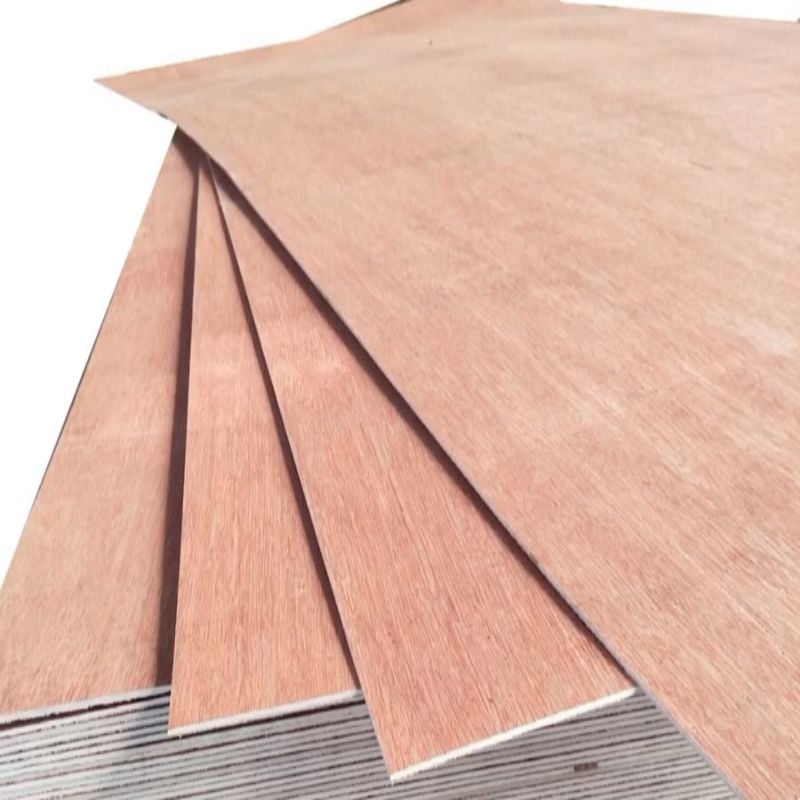

2. Smooth, Uniform Surface

Plywood provides a smooth and consistent surface suitable for painting, laminating, or veneering. It is ideal for furniture, cabinets, wall panels, and decorative finishing.

3. Lightweight but Durable

Despite being lightweight, plywood offers excellent load-bearing capacity. It is easy to transport, handle, and install, making it perfect for both small-scale projects and large construction works.

4. Versatile Applications

Plywood can be used for construction, furniture, packaging, flooring, marine projects, and more. It adapts well to both indoor and outdoor environments depending on the type of adhesive used.

5. Cost-Effective and Eco-Friendly

Manufactured from thin veneers peeled from sustainably grown trees (such as acacia, eucalyptus, pine, or birch), plywood maximizes raw material usage and reduces waste — making it both economical and environmentally friendly.

Technical Specifications

-

Material: Acacia, Eucalyptus, Pine, Birch, or Mixed Hardwood

-

Thickness: 3 mm – 30 mm (customizable)

-

Size: 1220 x 2440 mm (4 x 8 ft) standard; other sizes available upon request

-

Core: Full hardwood, poplar, or combi-core

-

Glue Type: MR (Moisture Resistant), E0/E1/E2 (Formaldehyde emission standard), WBP (Water Boil Proof)

-

Surface Finish: Sanded / Unsanded, Veneered, Film Faced, or Melamine Coated

-

Density: 550 – 750 kg/m³

-

Standard: CARB P2, CE, FSC, ISO9001, JAS Certified

Types of Plywood

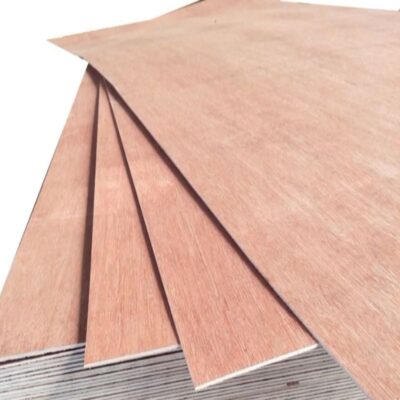

1. Commercial Plywood (Interior Grade)

Used mainly in furniture, cabinets, and wall paneling. Bonded with MR glue (moisture resistant) for interior use.

2. Marine Plywood (Exterior Grade)

Manufactured with WBP glue for high water resistance, making it ideal for shipbuilding, outdoor furniture, and humid environments.

3. Film-Faced Plywood

Covered with a phenolic film for construction formwork and concrete shuttering. Offers a smooth, reusable surface.

4. Decorative Plywood (Veneer or Melamine)

Laminated with natural wood veneers (oak, walnut, teak) or melamine paper for aesthetic appeal in interior design.

5. Structural Plywood

Engineered for load-bearing applications such as flooring, roofing, beams, and walls. Complies with strict construction standards.

Applications of Plywood

1. Construction and Architecture

-

Flooring, roofing, and wall sheathing

-

Concrete formwork and scaffolding boards

-

Temporary or permanent structures

2. Furniture Manufacturing

-

Cabinets, wardrobes, tables, chairs, and beds

-

Shelves, drawers, and paneling

-

Veneered plywood for high-end furniture

3. Interior Design and Decoration

-

Ceiling panels, wall cladding, partitions

-

Doors, decorative wall panels, and moldings

-

Customized finishes for modern interiors

4. Industrial and Packaging Use

-

Pallets, crates, and heavy-duty packaging boxes

-

Export packaging (ISPM 15 compliant)

-

Machinery transport supports

5. Marine and Outdoor Projects

-

Boat building, decking, and outdoor furniture

-

Exterior walls and architectural facades

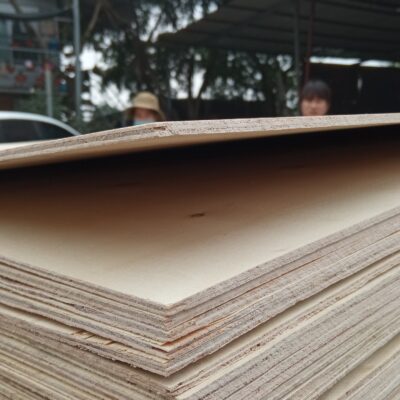

Production Process

-

Log Peeling: Selected logs are peeled into thin veneers using rotary cutting machines.

-

Drying: Veneers are dried to a precise moisture level to prevent defects.

-

Adhesive Coating: Glue is evenly applied to each veneer layer.

-

Stacking: Veneers are laid crosswise with alternating grain directions.

-

Hot Pressing: Layers are pressed under high temperature and pressure to form solid panels.

-

Trimming and Sanding: Edges are cut to size, and surfaces are smoothed.

-

Grading and Quality Inspection: Panels are checked for thickness, bonding, and appearance.

Quality and Export Standards

Our plywood products meet international standards for strength, durability, and environmental safety:

-

CARB Phase 2 / E0 / E1 certified for low formaldehyde emissions

-

FSC and PEFC certified for sustainable wood sourcing

-

ISO 9001:2015 quality management system compliance

-

JAS and EN 636 certification for export

We supply plywood globally for clients in Asia, the Middle East, Europe, and North America, offering custom thicknesses, surface finishes, and packaging according to export requirements.

Why Choose Our Plywood?

-

100% sustainable, legally sourced wood materials

-

Precision-engineered and hot-pressed for maximum durability

-

Excellent bonding strength and moisture resistance

-

Competitive factory-direct pricing for bulk orders

-

Fast delivery and reliable export logistics

-

Custom OEM & ODM options available

Conclusion

Plywood is more than just an engineered wood panel — it’s the backbone of modern furniture, architecture, and design. Its strength, flexibility, and eco-friendly production make it an essential material in both domestic and international markets.

Whether you are a furniture manufacturer, contractor, or exporter, our plywood products offer superior performance, consistent quality, and sustainable value for all your applications.

We provide a wide range of plywood — from commercial to marine, structural to decorative — customized to meet your specific project needs and international standards.