38. Modern Electrical, Plumbing & Lighting Solutions for Industrial Facilities

Modern Electrical, Plumbing & Lighting Solutions for Industrial Facilities

Discover modern electrical, plumbing, and LED lighting solutions for industrial facilities. Learn why PPR, HDPE, uPVC pipes and industrial LED lights are the optimal choice for efficiency and cost savings.

1. Why Do Industrial Facilities Need Optimized Systems?

Industrial plants require high safety, efficiency, and energy savings. A durable plumbing system combined with effective lighting not only reduces operational costs but also improves productivity.

Plumbing systems: Ensure continuous water supply and drainage, resistant to high pressure and harsh environments.

Lighting systems: Provide clear, stable lighting, reducing workplace hazards while saving energy.

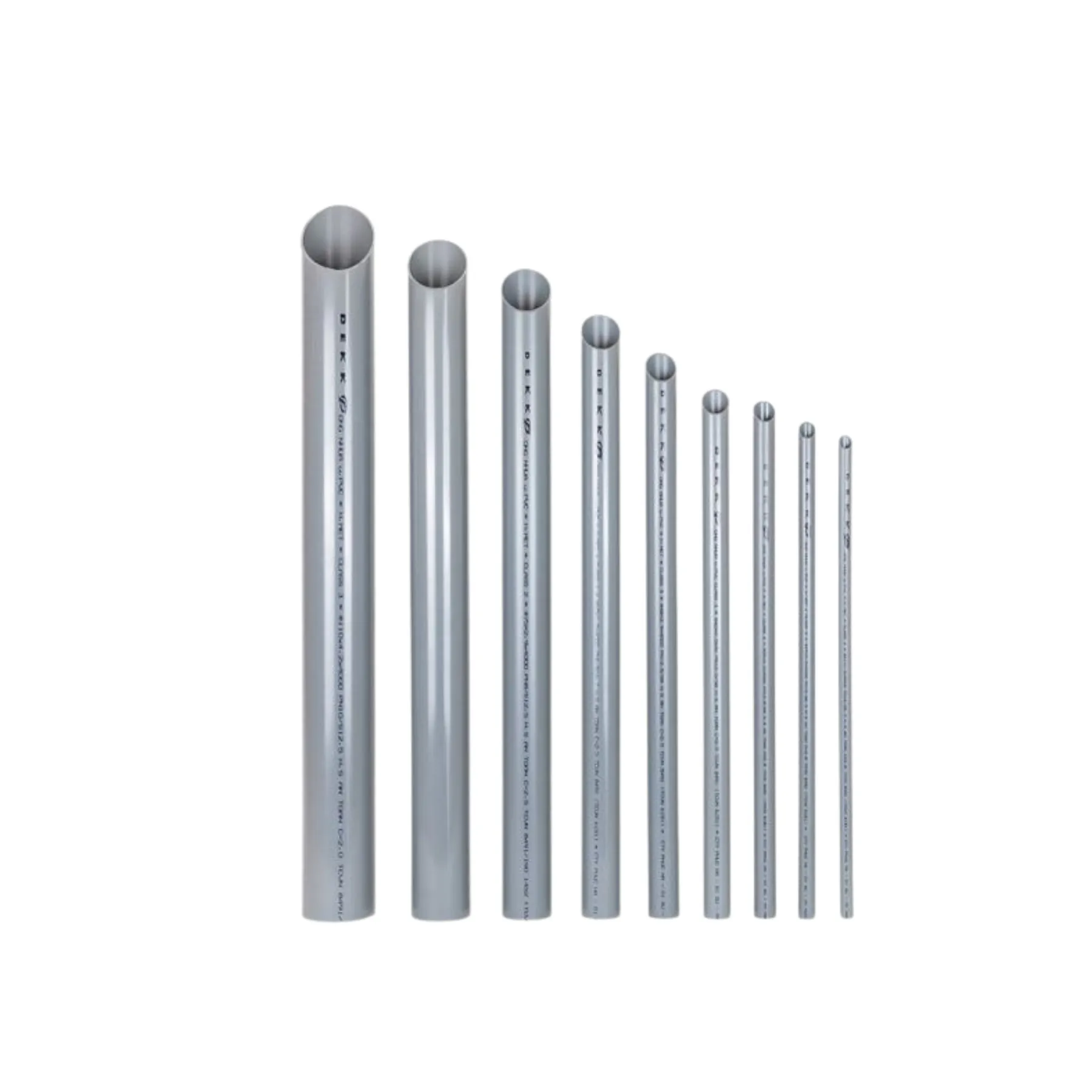

2. Modern Pipe Solutions for Industrial Facilities

2.1. PPR Pipes – Heat & Pressure Resistant

Advantages:

Withstand temperatures up to 95°C, corrosion-free, and durable for over 50 years.

Heat-fusion joints ensure leak-free connections.

Applications:

Hot and cold water systems in production areas.

Light fluid transport in industrial operations.

2.2. uPVC Pipes – Ideal for Drainage & Irrigation

Advantages:

Affordable and easy to install.

Resistant to mild chemicals and humid conditions.

Applications:

Industrial wastewater drainage systems.

Cold water supply for factories and workshops.

2.3. HDPE Pipes – Exceptional Strength & UV Resistance

Advantages:

Flexible, impact-resistant, and UV-protected.

Non-scaling interior walls ensure smooth water flow.

Applications:

Outdoor water supply, fire protection systems.

Underground piping systems.

2.4. UV-Protected Pipes – Outdoor Durability

UV-coated pipes are designed for outdoor applications, ensuring long-term weather resistance, anti-aging properties, and lasting performance.

3. LED Lighting Systems for Industrial Facilities

3.1. Why Use Industrial LED Lighting?

Energy-saving: LED lights reduce power consumption by 60–80% compared to fluorescent or incandescent bulbs.

Long lifespan: 30,000 – 50,000 hours, reducing replacement costs.

High-quality light: Flicker-free, bright, and comfortable for the eyes.

Shock and vibration resistance: Ideal for factory environments.

3.2. Popular Types of LED Lights in Industrial Settings

LED High Bay Lights: Perfect for high-ceiling production areas, providing strong and uniform lighting.

LED Tube Lights: Energy-efficient replacements for fluorescent tubes.

LED Panel Lights: Offer soft, wide-area illumination for offices and work areas.

LED Floodlights: Outdoor lighting for warehouses, yards, and loading docks.

3.3. LED vs. Traditional Lighting

Criteria LED Lights Traditional Lights

Lighting Efficiency 80–100 lm/W 10–15 lm/W

Energy Savings 60–80% Low

Lifespan 30,000 – 50,000 hours 1,000 – 5,000 hours

Vibration Resistance Excellent Poor

Long-term Costs Low maintenance Higher maintenance costs

4. Real-World Applications

Piping: Water supply, drainage, chemical fluid transfer, and irrigation systems.

LED Lighting: Factory floors, offices, warehouses, and quality inspection areas.

5. Benefits of Modern Electrical & Lighting Systems

Reduced operational costs: Lower water and electricity bills due to high-efficiency systems.

Enhanced productivity: Bright, stable lighting improves worker focus and safety.

Eco-friendly and safe: Both high-quality pipes and LED lights are non-toxic and recyclable.

Minimal maintenance: Durable systems with fewer breakdowns.

6. Tips for Selecting the Right Products

Choose pipes with international certifications: ISO, DIN, TCVN for reliability.

Opt for high-quality LED chips: Brands like Bridgelux, Samsung, or LG ensure brightness and longevity.

Design a unified system: A well-planned electrical and plumbing setup guarantees long-term efficiency.

7. Conclusion

Investing in modern piping systems and industrial LED lighting is a smart choice for facilities aiming to maximize efficiency, save costs, and ensure workplace safety. This approach represents a sustainable and future-proof solution for industrial construction.